-

Mobile phone: 13724352725

-

Email: liliangbin@szsyjm.com

-

Phone: 0755-22715304

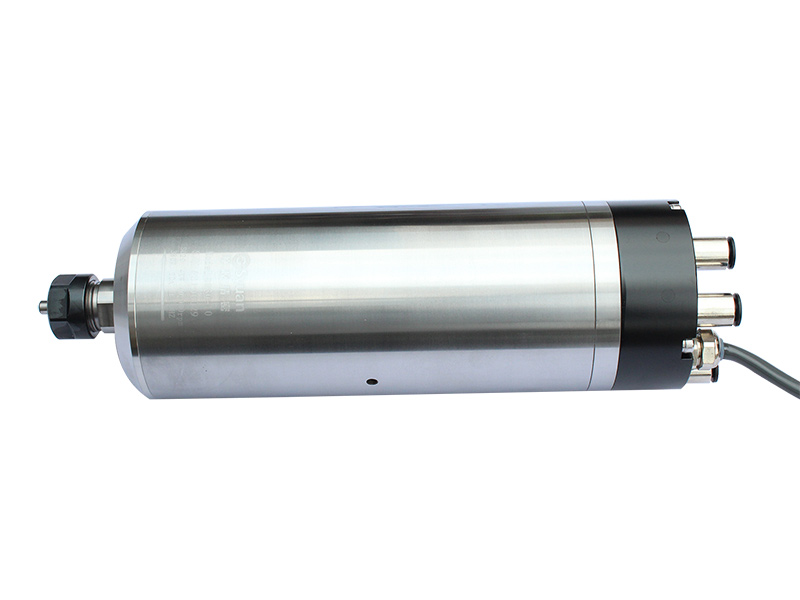

Electric spindleIt has the advantages of compact structure, light weight, low inertia, low noise, and fast response speed. Due to its high speed and high power, it simplifies machine tool design and is easy to achieve spindle positioning. It is an ideal structure in high-speed spindle units. The electric spindle bearing adopts high-speed bearing technology, which is wear-resistant and heat-resistant, and has a service life several times longer than traditional bearings. Static pressure bearings, power bearings, composite ceramic bearings, or electromagnetic suspension bearings are commonly used in electric spindles. Dynamic and static bearings have high stiffness and damping, which can greatly improve machining efficiency, machining quality, extend tool life, and reduce machining costs. Most of these bearings have an infinite lifespan.

At present, composite ceramic bearings are widely used in electric spindle units. The rolling elements of these bearings use hot pressed Si3N4 ceramic balls, and the bearing rings are still steel rings. They have a high degree of standardization, require minimal changes to the machine tool structure, and are easy to maintain. Electromagnetic suspension bearings have good high-speed performance, high accuracy, and are easy to diagnose and monitor online. However, due to the complexity of electromagnetic measurement and control systems, this type of bearing is expensive and has remained high for a long time, and has not been widely used to date.

Due to the diverse demands of consumers and the need for producers to reduce costs, various production systems with high productivity and flexibility have gradually been established, among which automatic tool changing CNC machine tools undertake the core task. In recent years, there have been further requirements for high speed, high precision, and high efficiency in improving the machining efficiency of machine tools. People have been continuously developing technologies for spindle, feed, tool change, and other systems. Therefore, functional components such as electric spindle drive units, ball screws, and linear guides have also emerged accordingly.

Electric spindle, also known as built-in motor spindle unit, is mainly characterized by the motor being built into the spindle to directly drive the spindle, thereby achieving the integration of motor and spindle functions. It is a direct drive method that omits intermediate transmission components such as gear transmission and variable speed devices (such as belts and couplings).

Electric spindle is a product of the fusion of electric motor and spindle, and the rotor of the electric motor is the rotating part of the spindle. In theory, an electric spindle can be seen as a high-speed electric motor. The key technology is dynamic balancing at high speeds:

The electric spindle is a high-precision actuator, and the main factors affecting the rotation accuracy of the electric spindle are:

The main spindle errors include roundness error of the spindle bearing journal, coaxiality error (causing deviation of the spindle axis), and perpendicularity error between the axial bearing surface of the spindle journal and the axis (affecting the axial displacement of the spindle).

Bearing errors include roundness errors of sliding bearing inner holes or rolling bearing raceways, waviness errors of sliding bearing inner holes or rolling bearing raceways, shape and size errors of rolling bearing rollers, perpendicularity errors between bearing positioning end faces and axis lines, parallelism errors between bearing end faces, bearing clearances, and force deformation during cutting.

E-mail:liliangbin@szsyjm.com

Address:A2 Building,Second row,Baishixia west area,Fuyong Town, Baoan District, Shenzhen