-

Mobile phone: 13724352725

-

Email: liliangbin@szsyjm.com

-

Phone: 0755-22715304

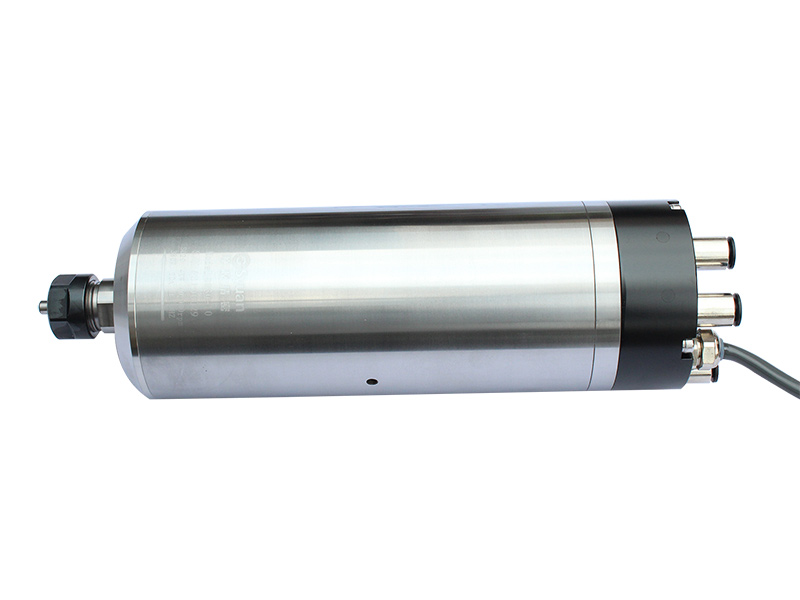

Electric spindle is a new technology that has emerged in the field of CNC machining. Simply put, it is a combination of spindle and spindle motor. Looking back at the development process of the past decade, the demand for precision instruments is enormous. The electric spindle is the intermediate component of high-speed CNC machine tools, and its function directly determines the high-speed machining function, machining accuracy, and output power of the machine tool. How to operate electric spindle maintenance?

The operation of an electric spindle not only requires high speed, but also high angular deceleration and acceleration, and quick stopping in a specified direction, which puts strict requirements on its layout description, production, and control. At the same time, it also brings a series of technical problems such as heat dissipation, smoothness, and fine control of the electric spindle.

It is necessary to make corrections to the electric spindle and handle these issues properly in order to ensure stable and reliable high-speed operation of the spindle and achieve efficient precision machining. As an intermediate component in mechanical processing, the electric spindle combines the spindle of the machine tool with the shaft of the communication servo motor, and directly installs the stator and rotor of the spindle motor into the spindle assembly. Through precise dynamic balance calibration, it has excellent reverse accuracy and stability, forming a good high-speed spindle unit, also known as a built-in electric spindle, which does not use a gear transmission pair, thus achieving zero drive of the machine tool spindle system. After being powered on, the rotor directly moves the main shaft.

As the electric spindle is a high-speed precision component, it is necessary to protect the maintenance timing of the electric spindle:

The radial runout of the far end of the electric spindle spindle (250 millimeters) is usually required to be 0.012 millimeters (12 micrometers), tested twice a year.

The axial runout of the electric spindle is usually required to be 0.002mm (2m), and it should be tested twice a year.

The extension interval when pulling the cutting rod and loosening the knife is 10.50.1mm (taking HSK63 as an example), tested four times a year.

The radial runout of the taper hole of the electric spindle is usually required to be 0.002mm (2m), and it should be tested twice a year.

E-mail:liliangbin@szsyjm.com

Address:A2 Building,Second row,Baishixia west area,Fuyong Town, Baoan District, Shenzhen