-

Mobile phone: 13724352725

-

Email: liliangbin@szsyjm.com

-

Phone: 0755-22715304

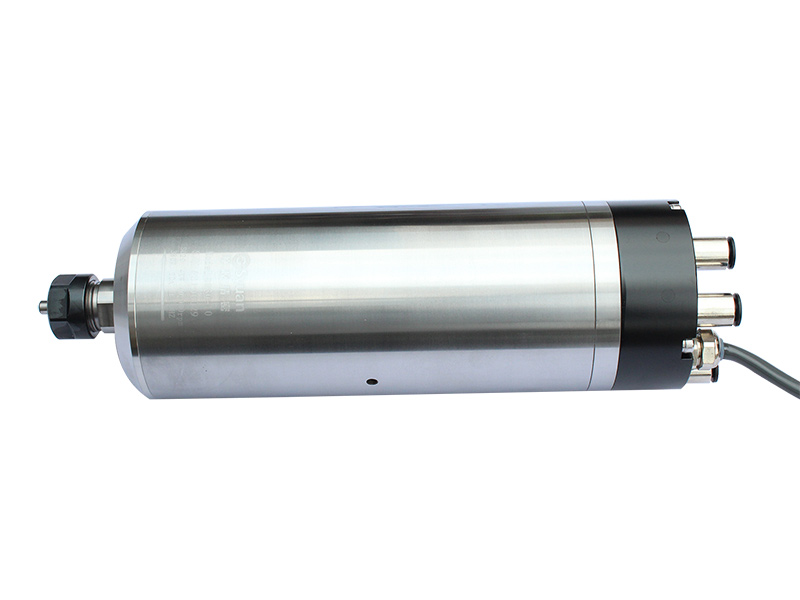

whenElectric spindleWhen rotating at high speed, its bearings generate a large amount of heat, causing the spindle temperature to rise, and the cutting tools installed at the end of the electric spindle also generate a large amount of heat during high-speed cutting. Therefore, the heat dissipation problem of electric spindles during operation has attracted widespread attention, and the structural design of electric spindles needs to consider heat dissipation issues.

During high-speed operation, power loss (including mechanical and electrical losses) occurs inside the electric spindle motor, causing the motor to heat up. Due to the installation of the electric spindle motor inside the spindle unit housing, the electric spindle motor cannot directly use a fan for heat dissipation, and the natural heat dissipation conditions are also relatively poor. The research results show that when the motor rotates at high speed, the working temperature of the motor rotor reaches 140-160 ℃, and the temperature of the stator also reaches 45-85 ℃. The heat generated by the electric motor will be directly transferred to the spindle, causing thermal deformation of the spindle and resulting in machining errors.

The purpose of the electric spindle cooling circuit is to maintain a constant spindle temperature, which is independent of the spindle speed. This can prevent the spindle front end from stretching, protect the spindle bearings, and ensure that the spindle accuracy is not affected by motor heating. The cooling circuit of the motor mainly focuses on the cooling of the motor stator. As long as the temperature of the stator is controlled within a lower range, the temperature of the motor can be controlled. The cooling method is to use external circulating water coolant to forcibly cool the motor stator, enhance the external heat dissipation ability of the motor, and keep the outer shell of the spindle part at room temperature; Tool cooling is optional, with the option to choose external cooling or internal cooling, or to choose both internal and external cooling simultaneously. When using the tool inner hole for cooling, the coolant passes through the hole in the middle of the rotary distributor under high pressure, opens the one-way valve, and sprays out from the middle hole of the handle (including the tool).

It is necessary to take heat dissipation measures because if the temperature is too high, it will directly affect the normal operation of the electric spindle. Therefore, everyone must pay attention to the temperature of the electric spindle during its operation. If poor heat dissipation is found and cooling measures cannot be implemented, it is best to promptly report the problem to the manufacturer and have professional technicians solve it for you.

E-mail:liliangbin@szsyjm.com

Address:A2 Building,Second row,Baishixia west area,Fuyong Town, Baoan District, Shenzhen