-

Mobile phone: 13724352725

-

Email: liliangbin@szsyjm.com

-

Phone: 0755-22715304

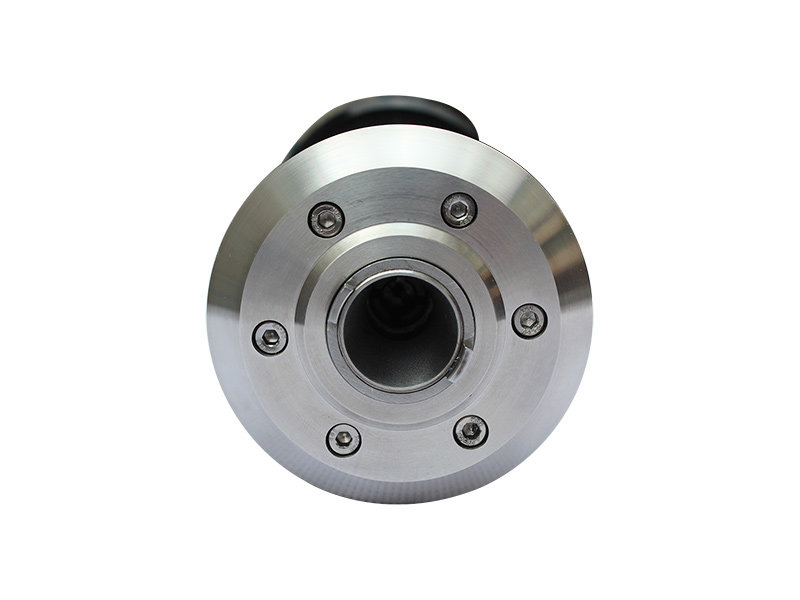

1. When cleaning the electric spindle, do not use compressed air to prevent dust from entering the spindle clearance and damaging the spindle bearings;

2. When cleaning the area around the electric spindle, although the spindle is stopped, the machine tool is powered on, and it is necessary to ensure that the spindle bearings are in a state of air curtain protection;

3. Pay attention to using cutting fluid on the tool, not on the end of the spindle;

4. The tool handle installed on the electric spindle should be cleaned regularly with a clean soft cloth to prevent dust from entering the spindle. When not in use, a tool should also be left to protect the taper hole of the spindle.

5. For new electric spindles or electric spindles that have not been used for more than a month, low-speed rotation should be ensured at the beginning of operation, and it is better to preheat the spindle to idle.

6. In order to ensure the high precision of the electric spindle, only precise dynamic balancing standard tools can be used during high-speed operation, and the electric spindle is preheated for 30 minutes to achieve thermal stability.

E-mail:liliangbin@szsyjm.com

Address:A2 Building,Second row,Baishixia west area,Fuyong Town, Baoan District, Shenzhen