-

Mobile phone: 13724352725

-

Email: liliangbin@szsyjm.com

-

Phone: 0755-22715304

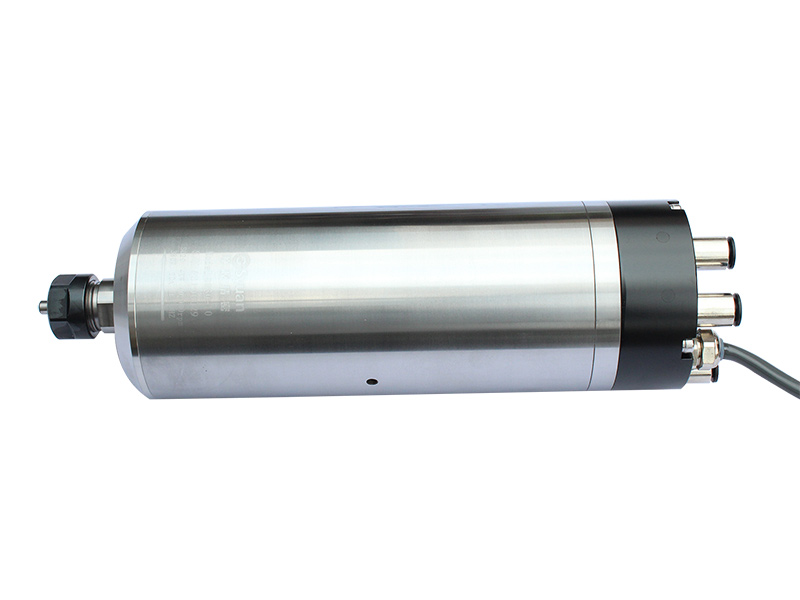

1. Stop the collision. Absolutely prohibit severe impact, especially at the end and front cover of the spindle, otherwise it will damage the precision bearings and spindle accuracy, resulting in spindle reversal and loss of unfolding accuracy.

2. Accurate placement and clamping. Before installation, it should be confirmed that the spindle motor is in normal condition, the surface of important fingers is not damaged, and the spindle rotates lightly and evenly.

3. Placement of clamp caps and cutting tools. The placement of cutting tools needs to ensure the accuracy of reverse rotation, otherwise it will breed severe vibrations, affect the quality and compliance of engraving (milling), and affect the service life of bearings.

4. Start up. For newly used spindle motors, it is advisable to run at low speed first and start at half speed to run 0. 5-1. 0 hours, then enter the highway. Usually, the spindle motor is started by frequency and voltage regulation, and efforts should be made to prevent sudden full pressure starting. The startup time is about 10 seconds to complete.

5. Operation. During normal operation, it is necessary to listen, touch, and check three times. Even if sudden braking occurs, the engine should be turned off in real time when the tool gets stuck. Listen to the sound of the spindle motor running for any dry friction or abnormal noise, and turn off the engine in real time for inspection; Check if the heating and vibration environment of the front cover or sleeve is stable. If the heating and vibration intensify, turn off the vehicle and check in real time; Check if the quality of the processed parts is stable, and in case of significant changes, stop the machine in real time for inspection.

Proper maintenance and upkeep can make the electric spindle work better, but while paying attention to maintenance is important, the selection of bearings for the engraving machine spindle is also crucial, as it directly affects the lifespan and performance of the machine tool or spindle. Therefore, it is recommended that you purchase qualified products.

E-mail:liliangbin@szsyjm.com

Address:A2 Building,Second row,Baishixia west area,Fuyong Town, Baoan District, Shenzhen