-

Mobile phone: 13724352725

-

Email: liliangbin@szsyjm.com

-

Phone: 0755-22715304

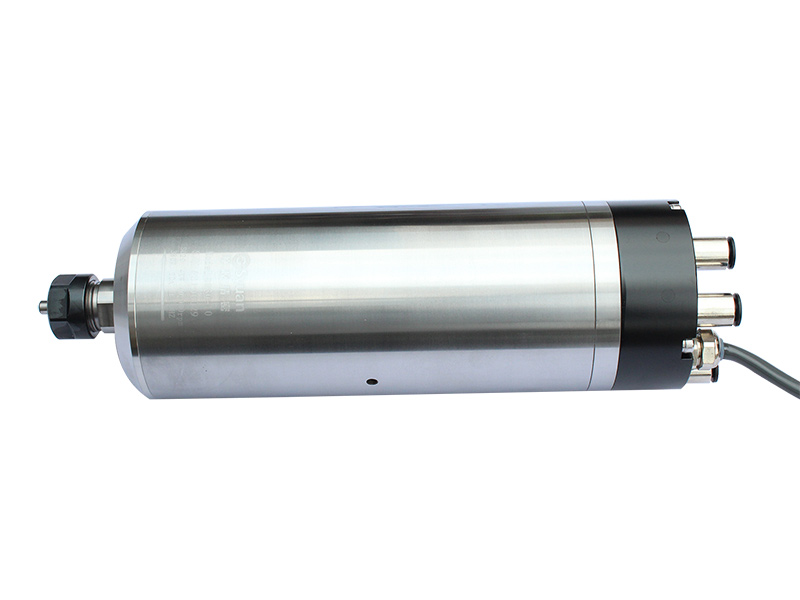

Precision electric spindle is an important component of high-speed machine tools. In daily production and use, it is important to pay full attention to the lubrication of the electric spindle, especially the bearing part. Below are several common lubrication methods.

Precision electric spindleThe commonly used lubrication methods for bearings include grease lubrication, oil mist lubrication, oil air lubrication, jet lubrication, and under ring lubrication.

1. Oil air lubrication refers to a small amount of lubricating oil being regularly and quantitatively carried by compressed air along the walls of a dedicated oil air pipeline to the lubrication area of the bearing, without being atomized. The lubricating oil of the precision electric spindle provides lubrication, while compressed air drives the movement of the lubricating oil and cools the bearings. Oil and gas are always separated, which is beneficial for the recovery of lubricating oil but does not pollute the environment. When implementing oil-gas lubrication, it is generally required that each motorized spindle bearing has a separate oil-gas nozzle, which has strict requirements on the position of bearing spray, otherwise it is difficult to ensure the lubrication effect, and the oil-gas lubrication effect is also affected by the compressed air flow and oil-gas pressure. Generally, increasing the air flow rate can improve the cooling effect, while increasing the oil and air pressure can not only improve the cooling effect, but also help the lubricating oil reach the lubrication area. Therefore, increasing the oil and air pressure can help improve the speed of the bearing. Experiments have shown that increasing the pressure ratio and using conventional pressure for oil air lubrication can increase the bearing speed by 20%.

2. Precision electric spindles do not require any equipment to add grease for lubrication, which is a commonly used lubrication method for low-speed spindles.

3. Electric spindles with DN values above 1.0 × 106 often use oil lubrication, where oil mist lubrication is the process of atomizing lubricating oil (such as turbine oil) through pressure air to lubricate the bearings of the electric spindle. This method is easy to implement, with simple equipment. Oil mist can not only lubricate bearings, but also cool them. However, oil mist is not easy to recover, causing serious environmental pollution and gradually being replaced by new oil air lubrication methods.

4. Precision electric main shaft ring lubrication is an improved lubrication method, which is divided into ring oil lubrication and ring oil air lubrication. When oil or oil air lubrication under the ring is used, the oil or oil air is sprayed into the lubrication area from the inner ring of the bearing. Under the action of centrifugal force, the lubricating oil of the motorized spindle is easier to reach the lubrication area of the bearing. Therefore, the effect is better than that of ordinary spray lubrication and oil air lubrication, which can further improve the speed of the bearing. For example, for ordinary oil air lubrication, the dn value of angular contact ceramic ball bearing is about 2.0 × 106. Increasing the oil air pressure can increase the dn value to 2.2 × 106, but the oil air lubrication under the ring can achieve 2.5 × 106.

5. When precision electric spindles use jet lubrication, high-pressure lubricating oil is directly used to lubricate and cool the bearings, which consumes a lot of electricity and is costly. It is commonly used in ultra high speed spindles with DN values of 2.5 × 106 or more.

E-mail:liliangbin@szsyjm.com

Address:A2 Building,Second row,Baishixia west area,Fuyong Town, Baoan District, Shenzhen