-

Mobile phone: 13724352725

-

Email: liliangbin@szsyjm.com

-

Phone: 0755-22715304

From a usage perspective, servo motors are mainly responsible for the feed of machine tools, causing the workpiece to move towards the tool or the tool to move towards the workpiece, mainly achieving cutting work, which requires high torque and control accuracy.Electric spindleMainly responsible for driving the spindle of machine tools, driving the rotation of workpieces or tool heads, with high requirements for constant power characteristic output, in order to meet sufficient torque output capability at different speeds. Therefore, in the design, these two types of motors will undergo targeted parameter optimization according to their respective application requirements.

Difference 1: Principle difference

Electric spindle is a precision asynchronous motor. Due to the requirements of high motion control, good dynamic characteristics, large speed range, and high position control accuracy for CNC machine tools, dedicated servo motors are needed.

Its principle is the same as that of a regular squirrel cage motor. The biggest difference between synchronous servo motors and asynchronous motors is the rotor structure. The rotor of a synchronous motor has staggered magnetic poles, so corresponding detection elements are needed to detect the position of the rotor. When replacing these detection components, they also need to be readjusted.

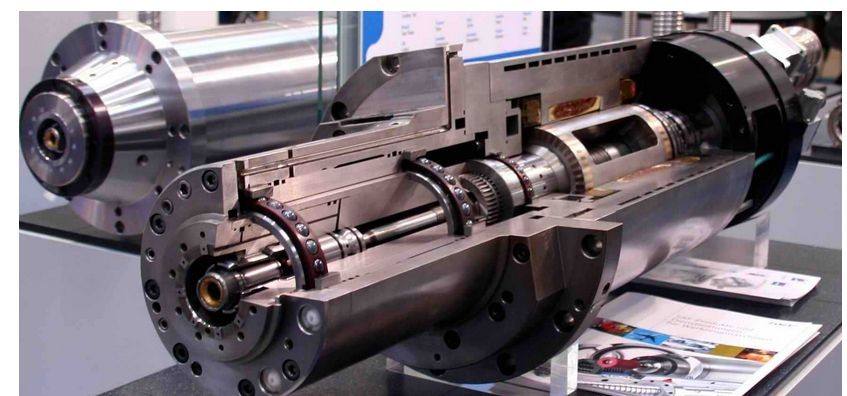

Difference 2: Structurally

In fact, the principles of these two motors are basically the same, but their structures and detection devices are different. The communication servo system adopts 1FT5 motor, and the digital servo system adopts 1FT6 motor. The stator winding structure is different. The stator winding structure of the 1FT6 motor makes the motor current closer to sine and cosine waveforms.

Difference 3: Differences in usage

The motor uses a tachometer generator to detect speed, and Hall elements evenly distributed on the circumference of the motor are used to detect the relative position of the rotor, while the 1FT6 motor uses a position encoder to detect the motor speed. In addition to the traditional A, B, and R-phase sine and cosine signals, the motor encoder also utilizes two C-phase and D-phase sine and cosine signals to detect the position of the motor rotor.

Difference 4: Scope of work

The servo motor operates in a constant torque range between the minimum speed and the rated speed, andElectric spindleWorking in the constant power range between rated speed and maximum speed, becauseElectric spindleThe rated speed is usually very low to achieve a large speed range.

E-mail:liliangbin@szsyjm.com

Address:A2 Building,Second row,Baishixia west area,Fuyong Town, Baoan District, Shenzhen