-

Mobile phone: 13724352725

-

Email: liliangbin@szsyjm.com

-

Phone: 0755-22715304

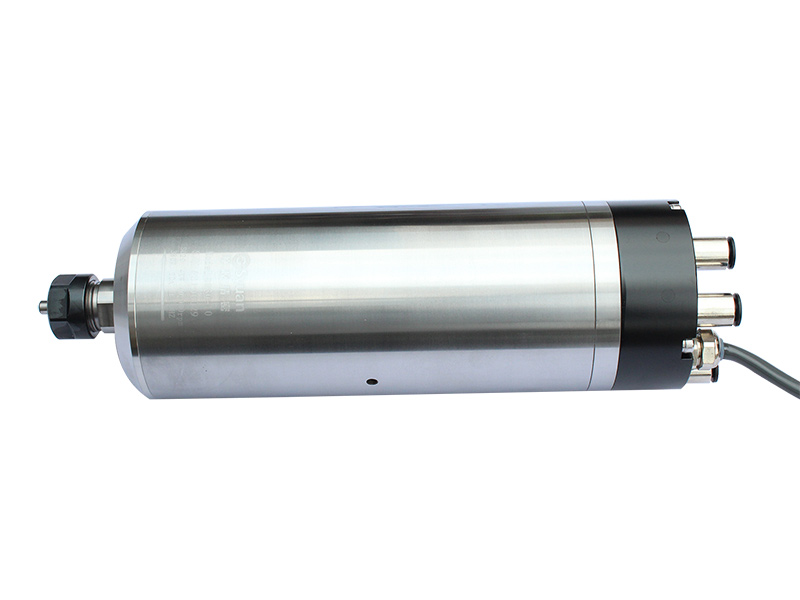

Electric spindleIt is a new technology in the field of CNC machine tools in the past decade, which integrates spindle and spindle motor. It is the "core" component of high-speed CNC machine tools, and its performance directly determines the high-speed machining performance of the machine tool.

Each component of the electric spindle is closely connected, and if one component is damaged, it will affect the overall operation of the electric spindle.

Therefore, in order to ensure the normal operation of the electric spindle, it is necessary to replace the electric spindle components in a timely manner when they are found to be damaged. If the bearings of the electric spindle are damaged, how should they be replaced? Below is an introduction to the disassembly and installation methods of electric spindle bearings.

1、 Application of electric spindle bearings

Use the already equipped electric spindle bearings and install them according to the "V" markings on the bearing surface. Note that the gasket used with the electric spindle should also have appropriate markings.

2、 Cleaning of electric spindle bearings

When cleaning the electric spindle bearings, the outer sleeve of the bearing should be tilted downwards or the inner sleeve should be tilted upwards for rotational cleaning. The bearings should be cleaned less than twice, and attention should be paid to not placing the electric spindle bearings in the wrong direction after cleaning.

3、 Smoothness of electric spindle bearings

Before installing the electric spindle bearings, the bearings, shaft sleeve holes, and main shaft of the electric spindle should be smoothed with lubricating oil. This is to facilitate the installation and ensure the smoothness of the bearings during the initial start-up of the electric spindle. It is important to use lubricating oil specifically designed for the electric spindle.

4、 Device for electric spindle bearings

When installing the electric spindle bearing, the rear end bearing should be installed first, the nut should be tightened, and the spring should be fixed on the bearing seat with butter. The spring cover should not be placed in the wrong position.

Fix the front end bearing of the device and secure the front end cover with a pre pressed bearing sleeve. The bearing of the device should use a dedicated sleeve, which is machined from a nylon rod. The shape is as follows: D is smaller than the outer diameter of the bearing, d is larger than the inner diameter of the bearing. Tighten the front nut and install the front and rear end caps. When installing the rear end cap, pay attention to the orientation of the air inlet hole. The sealing rings of the air inlet hole, water inlet hole, and water outlet hole should be intact and placed correctly.

5、 Check if the electric spindle bearing device is in place

After installing the electric spindle, check if the spindle device is in place. Use a wrench to push the spindle forward with force, and the spindle will move forward. If you let go, it will immediately bounce back.

E-mail:liliangbin@szsyjm.com

Address:A2 Building,Second row,Baishixia west area,Fuyong Town, Baoan District, Shenzhen