-

Mobile phone: 13724352725

-

Email: liliangbin@szsyjm.com

-

Phone: 0755-22715304

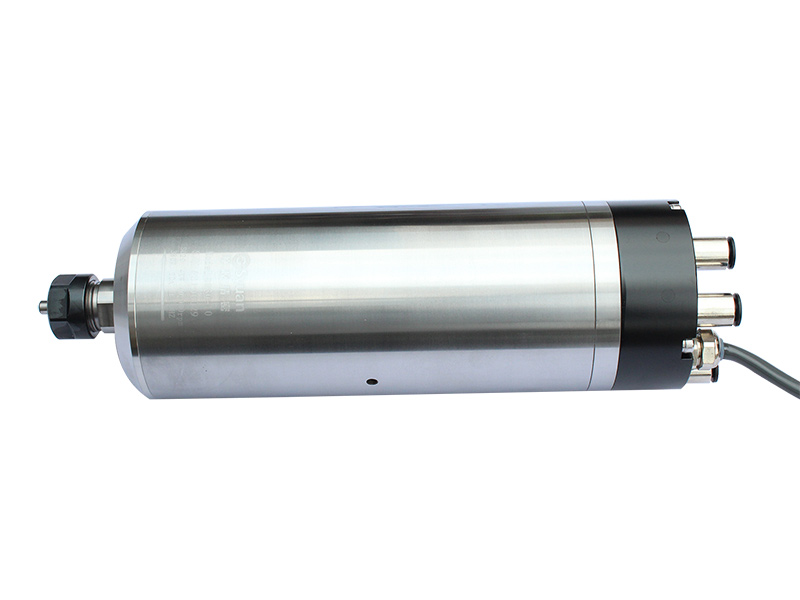

usedSynchronous electric spindleEveryone knows that the characteristics of synchronous electric spindles are compact structure, light weight, low inertia, low noise, and fast response. The ideal structure in high-speed spindle units is the lathe servo spindle, which has high speed and power, simplifies the design of machine tools, and is therefore easy to achieve spindle positioning. The bearings of synchronous electric spindles use high-speed bearing technology, which is wear-resistant and heat-resistant, and has a service life several times longer than traditional bearings. So maintenance of the electric spindle is also very important.

How to maintain synchronous electric spindle?

(1) Operators should use a vacuum cleaner to clean the debris on the synchronous electric spindle rotor end and motor wiring terminals after work every day, to prevent debris from accumulating on the rotor end and wiring terminals, in order to avoid debris entering the bearings and accelerating the wear of high-speed bearings; Avoiding debris from entering the wiring terminals and causing the motor to short-circuit and burn out.

(2) Every time the synchronous electric spindle changes the tool, the operator needs to unscrew the clamp of the pressure cap, and the electric spindle cannot change the tool directly by inserting and removing the tool! Operators should develop a habit of cleaning the card head and pressure cap after removing the cutting blade.

(3) After starting up every day, the operator needs to check the working status of the cooling water flow of the synchronous electric spindle, check whether the water pump is working normally, check whether the cooling water is contaminated by scale and microorganisms, check whether the pipeline status is normal, and ensure the normal circulation of the cooling water. Do not start the electric spindle without cooling water passing through it. Only under normal cooling conditions can the electric spindle be in good working condition. If the water pipe has a dead bend, resulting in poor water flow or blockage of the pipeline by dirt, it will cause the electric spindle to malfunction and affect the machining function.

E-mail:liliangbin@szsyjm.com

Address:A2 Building,Second row,Baishixia west area,Fuyong Town, Baoan District, Shenzhen