-

Mobile phone: 13724352725

-

Email: liliangbin@szsyjm.com

-

Phone: 0755-22715304

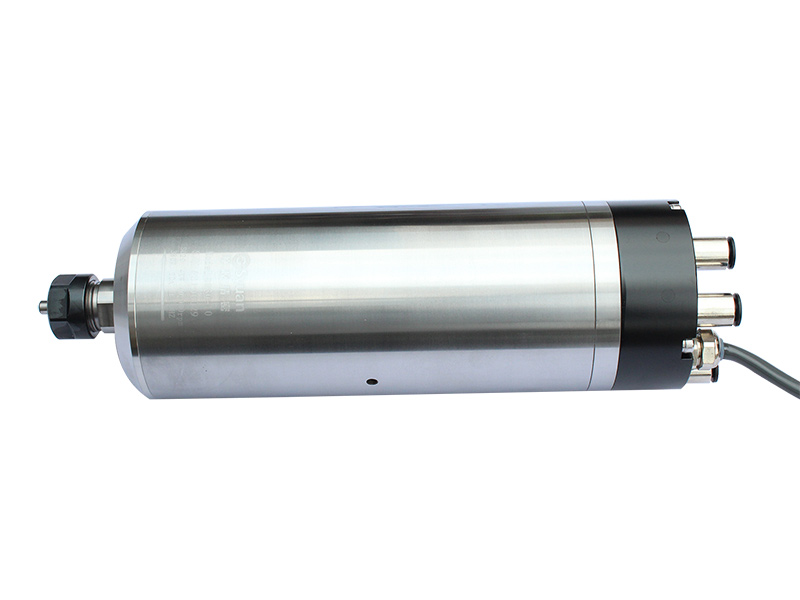

With the development of the economy, the machine tool industry has developed very well, so we have to talk about the electric spindle, which is one of its important components. As one of the important parts of machine tools, once a fault occurs, it will affect the operation of the entire machine.

The maintenance significance of the electric spindle is significant. The prominent problem of the electric spindle unit is the heating problem of the built-in motor. Due to the close proximity of the motor to the spindle bearing, if the heat dissipation problem of the main motor is not solved, it will also affect the reliability of the machine tool operation.

The main solution is to adopt a circulating cooling structure, which is divided into two types: external circulation and internal circulation. The cooling medium can be water or oil, so that the motor and front and rear bearings can be completely cooled. If there is a rattling sound on the spindle, it indicates that there is vibration and collision between the internal cage and the rolling body. When the load or radial clearance is large, this phenomenon is more likely to occur. To effectively avoid it, it is necessary to improve the accuracy of the cage, choose bearings with small clearance or add preload to the bearings.

Sometimes the electric spindle buzzes, which is an abnormal axial vibration of the motor. This phenomenon usually occurs in motors with poor lubrication and ball bearings at both ends in winter. It can be improved by adjusting the centering performance. Of course, it is more important to choose qualified products. The quality of the spindle will also affect the machining effect of the lathe, ensuring the machining effect of the lathe. Otherwise, the lathe will not work normally, which will delay normal work and cause unnecessary trouble. The effective way to reduce wear during use is lubrication. Lubrication treatment of bearings ensures good lubrication and cooling effects. Therefore, choosing reasonable lubrication is an important condition for ensuring normal operation.

E-mail:liliangbin@szsyjm.com

Address:A2 Building,Second row,Baishixia west area,Fuyong Town, Baoan District, Shenzhen